SHO NUT Performance Cams Page

Revised 12/16/19

We have worked with Colt Cams to come up with FOUR SHO

NUT Performance exclusive cam profiles. Colt

Cams is a company that specializes in high-quality cam grinding for a variety

of vehicle applications, including the SHO.

Our offerings are composed of four cam sets:

SHO NUT Performance Tri-Flow cams

SHO NUT Performance Plus 40 cams (Special order

only)

SHO NUT Performance Plus 20 cams (Special order

only)

SHO NUT Performance Plus 10 cams

The numbered name implies the additional lift

over a stock MTX cam for the first two numbered cams (Plus 40/20), and a

natural progression of numbers for the third numbered cam (Plus 10) (See below)

As a primer, here are the measured specs of the

stock cams:

MTX Intake 0.348”

Lift, 205° Duration @ 0.050”

MTX Exhaust 0.328”

Lift, 201° Duration @ 0.050”

ATX Intake 0.328”

Lift, 201° Duration @ 0.050”

ATX Exhaust 0.328”

Lift, 201° Duration @ 0.050”

The ATX Intake chain flange bolt holes are also

advanced 4 crankshaft degrees relative to the MTX cam. As the Intake chain flange is what drives the

Exhaust cam, this effectively advances the Exhaust cam in an engine with ATX

cams by 4 crankshaft degrees, which also reduces the overlap by 4 crankshaft

degrees. Compounded with less duration

on the ATX intake lobe, there is substantially less overlap with the stock ATX

cams. In total, there is 6 crankshaft

degrees less overlap, 4° due to the advanced exhaust cam, and 2° due to 4° less

intake duration (1/2 of the total duration difference). Note that if you are regrinding cams, it is

critical that both intake cams be either MTX or ATX, or you will have

mis-matched exhaust lobe centerlines between banks due to the 4° difference

between MTX and ATX exhaust cam timing, as driven by the intake cam

flanges. We carefully check each set of

camshafts to verify that we have matching intake cams for each set of cams

made.

To make our Plus 40 cams, we take MTX cores,

add a 0.055” lash cap, and grind a new profile ‘straight up’ (i.e. same

centerline as stock) which includes grinding the base circle approximately

0.055” and broadening the tip to increase the lift and increase the duration. In addition, quieting ramps are incorporated

into our lobe profile to keep the valve train quiet and lessen the shock on the

valve springs that you would otherwise get with extreme ramp rates. Quieting ramps are a new feature for SHO

performance cams. Since the tip is

broadened, it is impossible to get all 0.055” as additional lift, since the

stock lobe is quite pointy, and we need to account for wear etc. It is also not practical to grind more off

the base circle – we are nearly into the shaft of the cam as it is, and clearancing of the cam journals is required to get this far

(so the shims won’t hit the cam journals, since they are now 0.055” closer to

the shaft of the cam, and would otherwise hit the cam journals if the journals

were not clearanced properly, keeping the valves open

– a bad thing).

To make our Tri-Flow cams, we take MTX cores,

add a 0.055” lash cap, and grind a new profile which includes grinding the base

circle approximately 0.055” and broadening the tip to increase the lift and

increase the duration. For the

‘secondary’ lobe, which is mated the short fat runner that is only open over

~4000 RPM, we grind the same high lift/high duration ‘straight up’ lobe as our

Plus 40 cam. For the ‘primary’ lobe,

which is mated to the long skinny runner that is open all the time, we grind a

lobe that is lower in lift and duration than the secondary lobe, and is

retarded relative to the ‘straight up’ secondary lobe, to decrease overlap when

only the primary runner is being used before ~4000 RPM. The amount of primary lobe retardation is

such that the intake valves close at the same time. The idea is that when the secondaries are

closed below ~4000 RPM, you have less overlap, intake lift and duration than

when the secondaries are open above ~4000 RPM, and the runner to the larger

lobe is no longer blocked. This mimics the effect of variable valve timing and lift

without the usual hardware involved.

Increased lift, duration and overlap is generally detrimental to low RPM

operation, and advantageous to high RPM operation. Granted, there is an incomplete separation

between primary and secondary intake ports in the head, so some cross-over may

occur in the head, but the idea is that the direct air path is controlled by

the secondary throttle plates to keep the effect of the large lobe in RPM

ranges above ~4000 RPM when both runners are in use. Thus a Tri-Flow cam should have a smoother

idle and more low end power than a Plus 40, while losing little to the Plus 40

in the top end, when the long skinny runner is essentially a cork, and not

flowing much air flow relative to the short fat runner, and thus the lower

lift/duration lobe in the lower-flowing skinny runner is not much of a

penalty. Colt Cams discusses the

Tri-Flow technology in general here but

the setup for the SHO is somewhat unique, as a different runner is used for the

‘primary’ and ‘secondary’ lobes, instead of the usual use of identical runners

in other engines for both lobes. Their

use of ‘primary’ (large lobe) and ‘secondary’ (small lobe) is also reversed

relative to the normal SHO usage of the ‘primary’ as the low RPM runner which

uses the smaller lobe in our application, and the ‘secondary’ as the as the

high RPM runner which uses the larger lobe in our application. Thus the swirl

effect may not be the same in the SHO application.

To make our Plus 20 cams, we take ATX cores,

and as with the MTX cores, we add a 0.055” lash cap, and grind a new profile ‘straight

up’ (i.e. same centerline as stock) which includes grinding the base circle

approximately 0.055” and broadening the tip to increase the lift and increase

the duration. Since the ATX intake cores

have less lift to work with compared to MTX intake cores, even though we are

grinding 0.055” off the base circle, we can only get about 0.020” more lift

than a stock MTX intake cam, hence the ‘Plus 20’ name. Compared to a stock ATX intake cam, the

increase is just as dramatic as it is for an MTX intake cam, (going from a

stock ATX cam to a Plus 20 is approximately a 0.040”

increase in lift), but for our purposes, we will compare all cams to stock MTX

cams when quoting increases in lift etc.

Since the same exhaust cam is used for both MTX

and ATX engines, the core is the same, and thus our exhaust cam spec is the

same for Plus 40, Plus 20, and Tri-Flow Cams, i.e. approximately a 0.040”

increase in lift. In other words, the

‘Plus 40’ exhaust cam is used for the Plus 40, Plus 20 and Tri-Flow cams. Thus the Plus 20 is

really a Plus 20 intake / Plus 40 exhaust mix.

To make our Plus 10 cams, we take MTX cores,

add a 0.035” lash cap, and grind a new profile ‘straight up’ (i.e. same

centerline as stock) which includes grinding the base circle approximately

0.035” and broadening the tip to increase the lift and increase the

duration. As with the first two grinds,

quieting ramps are incorporated into our lobe profile to keep the valve train

quiet and lessen the shock on the valve springs that you would otherwise get

with high ramp rates. Since the tip is broadened, it is impossible to get all

0.035” as additional lift, since the stock lobe is quite pointy, and we need to

account for wear etc. Clearancing of the cam journals is not required with the

Plus 10 cam.

Here are the specs of the four cam offerings –

these are actual numbers and not some inflated ‘advertised’ number:

|

SHO NUT Performance Tri-Flow Cams |

|||||||

|

Specifications |

Compare to Stock MTX: |

Increase from Stock: |

|||||

|

|

Lift |

Duration @ 0.050 |

Lift |

Duration @ 0.050 |

Lift |

Duration @ 0.050 |

Overlap* |

|

Secondary Int. |

0.390 |

228° |

0.348 |

205° |

0.042 |

23° |

24.5° (S) 9.5° (P) |

|

Primary Int. |

0.375 |

218° |

0.348 |

205° |

0.027 |

13° |

|

|

Exhaust |

0.365 |

227° |

0.328 |

201° |

0.037 |

26° |

|

|

* Can be

increased or decreased 6 or 12 degrees with our adjustable camshaft sprockets |

|||||||

|

All

degree measurements are in crankshaft degrees. Divide by 2 for camshaft degrees. |

|||||||

|

SHO NUT Performance Plus 40 Cams |

|||||||

|

Specifications |

Compare to Stock MTX: |

Increase from Stock: |

|||||

|

|

Lift |

Duration @ 0.050 |

Lift |

Duration @ 0.050 |

Lift |

Duration @ 0.050 |

Overlap* |

|

Intake |

0.390 |

228° |

0.348 |

205° |

0.042 |

23° |

24.5° |

|

Exhaust |

0.365 |

227° |

0.328 |

201° |

0.037 |

26° |

|

|

SHO NUT Performance Plus 20 Cams |

|||||||

|

Specifications |

Compare to Stock MTX: |

Increase from Stock: |

|||||

|

|

Lift |

Duration @ 0.050 |

Lift |

Duration @ 0.050 |

Lift |

Duration @ 0.050 |

Overlap* |

|

Intake |

0.365 |

227° |

0.348 |

205° |

0.017 |

22° |

20° |

|

Exhaust |

0.365 |

227° |

0.328 |

201° |

0.037 |

26° |

|

|

SHO NUT Performance Plus 10 Cams |

|||||||

|

Specifications |

Compare to Stock MTX: |

Increase from Stock: |

|||||

|

|

Lift |

Duration @ 0.050 |

Lift |

Duration @ 0.050 |

Lift |

Duration @ 0.050 |

Overlap* |

|

Intake |

0.370 |

214° |

0.348 |

205° |

0.022 |

9° |

11° |

|

Exhaust |

0.345 |

214° |

0.328 |

201° |

0.017 |

13° |

|

The Tri-Flow cam is targeted at someone who

wants to reduce the negative effects of a ‘big cam’ at low RPM, while retaining

the ‘big cam’ effect at high RPM. Of course, both cam timing and overlap can be

independently adjusted with our SHO NUT Performance Adjustable Cam Sprockets.

The Plus 40 cam is targeted at someone who

wants maximum top end power in a motor with ported heads and dramatically

increased displacement, i.e. stroker or big-bore motor that is used for high

RPM road racing. The Plus 40 cam may not

produce any more power than the Plus 20 when put in a 3.0L or 3.2L with stock heads, but may have a rougher idle due to the increased

overlap. Due to the increased overlap, it is not recommended for forced

induction – use the Plus 20 for forced induction, as it has the same exhaust

cam, but less overlap. Of course, both

cam timing and overlap can be independently adjusted with our SHO NUT

Performance Adjustable Cam Sprockets.

The Plus 20 cam is targeted at modified cars

with stock heads and a 3.0L or 3.2L, including forced induction that

needs minimum overlap and maximum exhaust lift and duration. Note that the 4° exhaust cam advance/overlap

reduction (compared to an MTX cam set) in the ATX core is carried through to

the Plus 20 cam, and thus the Plus 20 cam set will have 4.5° less overlap than

the Plus 40 cam, while retaining the Plus 40 exhaust profile. As before, both cam timing and overlap can be

independently adjusted with our SHO NUT Performance Adjustable Cam Sprockets.

The Plus 10 cam is targeted at a stock or

near-stock motor, and should have more low end torque than the other two

numbered cams, by virtue of reduced lift and duration and overlap, and thus

boosting power all the way through the power band, compared to stock. As before, both cam timing and overlap can be

independently adjusted with our SHO NUT Performance Adjustable Cam Sprockets.

Pricing, including

lash caps and a shim rental and excluding core charges/refunds is listed on our

Performance page. Shipping/handling is

extra and is $45. This is waived if you

pick up the cams at Colt Cams.

The shim selection

for the rental is selected knowing that since these are ‘unworn’ lobes, the

required shims will be a few sizes thinner than we usually supply for worn

stock cams. If you know the shim sizes

in your motor, i.e. from your last 60K service, then let us know, and we can

choose the shim selection appropriately.

If you are

rebuilding a set of heads, and purchase oversize valves from us that have a

stem that is 0.055” longer than stock (above the keeper), you do not need lash

caps, and eliminating them from the supply allows the price to be reduced by $160. E-mail us if you are doing this.

Gaskets are

extra. It is recommended that you

purchase an upper gasket set (less head gaskets if you are not removing the

heads) to get all the gaskets you need for a cam change.

The core charge is

$100 for a set of used cams in good shape*, and must be MTX** – we no longer accept ATX cores as the

+20 is special order only, and we have plenty of ATX cores on hand. They MUST have good bearing journals*.

* lobe tip wear is

acceptable, since we grind so much off the tip to broaden it. Damaged lobes will be evaluated on a

case-by-case basis. Cam cores with

damaged bearing journals will be rejected.

** as mentioned

before the difference between the ATX and MTX cams are the intake cams. There are various ways of telling the intake

cams apart. Two are:

- Look for the KOA lettering on the intake

cam next to the wrench flats. If it

present and the lettering is obviously raised just like the exhaust cam,

it is an MTX intake cam. If it is

ground off the shaft of the cam (it may still be visible, but not raised,

or it may simply be an extra ground-flat ring around the cam, in the same place as the lettering on an exhaust

cam), then it is an ATX intake.

Make sure that both intake cams match in this respect to make sure

you have a matched set.

- Compare the intake lobe height to the

exhaust lobe height. The MTX intake

will have a taller lobe than the exhaust cam lobes by approximately 0.020”. The ATX intake will have a lobe the same

height as the exhaust cam lobes.

The core refund is $100 for MTX cores. Please note that it is NOT required to send in cores at all, if you wish to simply pay the core charge outright and keep your own stock cams, if it’s too much work/hassle to return cores to Colt, or you can’t find a shipping cost under $100.

If you can send cams

ahead of time, or have your own shims, you avoid the core charges. All cores are returned to Colt Cam’s **NEW**

addresses: (Colt

is only accepting cores sent via the Post office to their PO box at this time

as they work through a family emergency).

When sending in your

cams via couriers such as UPS, Fed-Ex, Greyhound bus etc..

Please send it to their physical address:

Colt Cams Inc.

2325 264th street

Aldergrove BC V4W 2L5

Canada

When sending your

cams via the post office please send it to their P.O. box mailing address:

Colt Cams Inc.

P.O. Box 1979

Aldergrove BC V4W 0A6

Canada

Phone: 604-856-3571

Fax: 604-856-3572

The best way to

package them is in individual cardboard or plastic tubes, and

put those tubes in a box. No matter what

you do, make sure there is lots of padding/separation between cams. This keeps

the flanges from rubbing on the cam journals.

If you are checking shipping costs, a set of cams weighs about 18 lb.

and fits nicely in a USPS game box (a ‘large flat rate box’ that is

24x12x3). If you use USPS (recommended,

UPS seems to be more aggressive about charging brokerage), a USPS game box

(large flat rate) Priority is~ $65 and takes 6-10 business days. UPS Standard to BC is about ~$45 with a

small business discount and takes 2-6 business days.

IMPORTANT!! – It is

VERY important that you write ‘Damaged camshafts for repair and return, value

less than $15’ on the package and the customs slip when you send it out. This is critical to ensure that the package

gets through Customs without any problems.

If you do not include the above wording on the box, or use excessive

insurance, we will adjust the core return by any customs/brokerage charges paid

to receive the cores.

IMPORTANT!! – be

sure to remove the cam gears as well as the shutter wheel on the end of the one

exhaust cam before you package them! If

you leave them installed, the cam gears will invariably rub on the cam journals

and damage them. Cams with damaged

journals will NOT be accepted as cores!

Camshaft break-in is

20 minutes at 2000 RPM, and don’t forget to assemble the cams with the provided

lube. A TwEECer

is a good way of setting your idle speed.

Want more technical

info and pictures? Keep reading ….

While the specs of the cams can tell a great

deal of the story, one way in which our cams really shine is the lobe-to-lobe

consistency. Here are caliper

measurements taken from a set of Plus 40 cams, and as you can see, the consistency

in lift is near-perfect, +/- 0.0005” (half a thou) across ALL lobes. In addition, the base circle consistency

across each cam is basically just as good, +/- 0.0015” (one and a half thou),

and even +/-0.0025” (two and a half thou) across all cams, so even the

cam-to-cam consistency is excellent.

This means that the selection range of shims required is now governed by

the consistency of the head and valves, and not the cam (see more below). Note that since these measurements were made

with a caliper, they are not exact as those made with a micrometer, or better

yet, a dial indicator with the cam mounted in the head or in V-blocks. However, caliper measurements are easy to

make, and reasonably repeatable, so for our purposes, it worked for what we were

trying to do.

Click here for individual

lift, base circle and lobe height measurements

In other words, the quality of the grind speaks

for itself. This level of consistency is

a new benchmark for SHO performance cams.

Here is a record of the shims required to shim

the above set of Plus 40 cams to 0.008” for the intake, and 0.012” for the

exhaust (middle of the spec for a blower car, as it’s not a good idea to shim a

blower car tightly). If they had been

shimmed to 0.006” and 0.010” (normal for a N/A car), each shim would have been

2 sizes thicker as noted as well. You

will notice that all lobes were +/-0.002 when measuring with a sample measuring

shim (2450, a common shim, used to measure the clearance to see what shim is

needed to achieve the correct clearance).

We have recorded the required shim spread - this low spread goes to

reinforce the consistency of these lobes. You will also notice that the

required shims are sizes that are readily available – we have plenty of these

sizes for our rental kits – no need to go searching for obsolete super thick or

super thin shims or even custom lash caps to make these super-consistent and

properly-sized cams fit. Of course, if

your heads have been rebuilt with new valves or reground seats, then you may

have shim size issues, but this relates to having changed the geometry of the

heads and valves, and NOT the cams. In

these cases, thicker or thinner shims, or custom lash caps may be

required. If you have had your heads

rebuilt with new valves and/or have had the seats reground, and need custom

lash caps, let us know, and we may be able to help you out.

Click here for sample

shims and clearances

As before, the quality of the grind speaks for

itself. This level of consistency in

required shims (and the ability to use standard-size shims for all lobes) is a

new benchmark for SHO Performance cams.

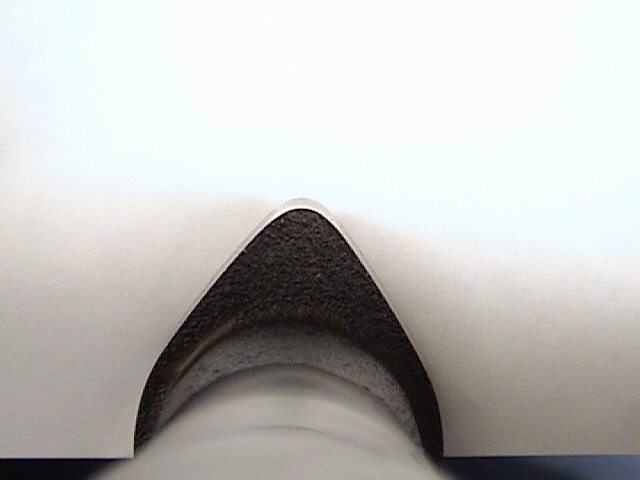

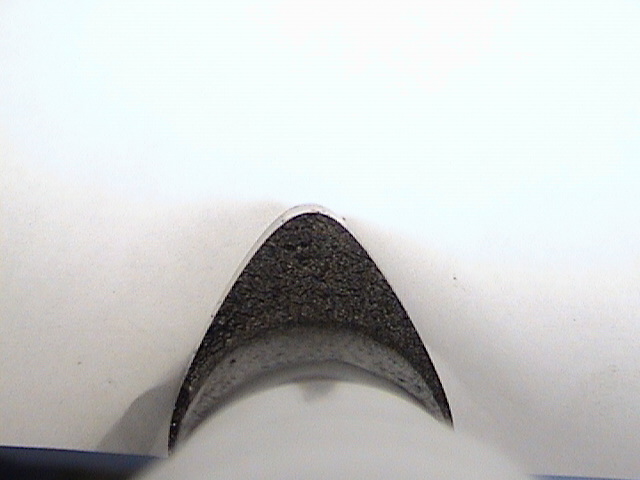

Pictures –

note how pointy the stock lobe tip is, and how broad the Plus 40 lobe tip is,

and notice how little is left of the base circle. Though not shown, the Plus 20 intake lobes

would look near identical to the exhaust lobes shown, since both ATX intake

lobes and exhaust lobes (MTX or ATX, both are identical) are the same, and thus

our grind is the same for both.

http://www.shonutperformance.com/Stock_intake_lobe.jpg

http://www.shonutperformance.com/Plus_40_intake_lobe.jpg

http://www.shonutperformance.com/Stock_exhaust_lobe.jpg

http://www.shonutperformance.com/Plus_40_exhaust_lobe.jpg

http://www.shonutperformance.com/Exhaust_lobes_plus_40_on_right.jpg